In today's quickly progressing technical landscape, sensing units play a crucial role in numerous sectors, offering important information for surveillance and control processes. Among the array of sensors offered, magnetostrictive displacement sensors have emerged as a famous choice for applications needing precise measurements. These gadgets utilize the principle of magnetostriction to detect adjustments ready, making them vital in many settings, from industrial automation to liquid level measurement.

When subjected to a magnetic field, magnetostrictive displacement sensors operate based on the phenomenon that certain products show a modification in length. These sensors commonly contain a waveguide or a rod made from magnetostrictive material, an electromagnetic field generator (normally a long-term magnet), and an analysis unit. When the device is triggered, a pulse transmission happens along the waveguide, leading to a time-dependent signal that can be measured. These sensing units attract attention as a result of their high precision, dimension variety, and resilience, making them the favored selection for suppliers and systems integrators looking for reputable dimensions.

In specific, magnetostrictive liquid level sensors are utilized to determine the levels of liquids in different containers and tanks, which is crucial for preserving operational efficiency in industries such as chemicals, pharmaceuticals, and food and beverage. The capability to provide continuous, real-time information enables operators to monitor the level of liquids, ensuring that procedures run efficiently and preventing possible overflow or lacks. This makes magnetostrictive liquid level sensors crucial devices in liquid monitoring systems.

Likewise, magnetostrictive position sensors expand the advantages of this innovation to wider applications, including machinery positioning and material handling remedies. By offering dependable and accurate position responses, these sensors enable automation systems to operate effectively and correctly, reducing downtime and enhancing efficiency. Essentially, magnetostrictive position sensing units function as vital components in a selection of mechanized and automated settings, where accurate position tracking is important.

For companies looking for to execute these sensors right into their systems, selecting the ideal manufacturer becomes critical. A trustworthy displacement sensor manufacturer will offer a variety of items that fulfill high requirements of dependability and performance. Many manufacturers specialize in developing both magnetostrictive and TEC (Thin Film Technology) displacement sensors, which give boosted functions for certain applications. TEC displacement sensing units, as an example, are recognized for their compact style and durable construction, making them appropriate for atmospheres where room is limited or conditions are testing.

Liquid level evaluates, especially those using magnetostrictive technology, are important for sectors where fluid monitoring is essential. The accuracy and dependability of magnetostrictive liquid level meters make certain that drivers can rely on the readings existing, helping to prevent the detrimental effects of inaccurate liquid level tracking. A manufacturer of liquid level assesses will usually supply products developed especially for various applications, from straightforward storage tanks to intricate chemical processing devices.

In addition to different series of magnetostrictive sensors, manufacturers commonly supply different product, such as R series, E-series, and M-series displacement sensors, catering to varied industrial requirements. Each of these series is designed with certain features, dependability aspects, and technical requirements targeted at different applications. R series displacement sensors might be developed for rugged environments, while E-series sensing units may accommodate applications requiring higher precision.

Floating ball level evaluates are another kind of liquid level dimension device. The simpleness of their style allows for effective procedure without the complexity of electronic components. While these mechanical systems function properly under lots of problems, they might lack the accuracy and real-time comments that electronic sensing units provide, especially in applications calling for rigorous adherence to operational specifications. Floating ball level determines can still play a crucial duty in particular setups, providing visual indicators of liquid levels in a cost-effective manner.

One more promising modern technology in the realm of liquid level measurement is the putting-into-type liquid level meter. These devices incorporate innovative measurement techniques with user-friendly user interfaces, allowing operators to attain exact liquid measurements effortlessly. Producers are progressively concentrating on developing such systems, which can consist of attributes that suit various ecological conditions and certain liquid kinds.

The connection of innovation and sector emphasizes the necessity for effective dimension options. Across various industries, incorporating accurate measurement devices, such as magnetostrictive sensors, has actually come to be crucial. Their application goes beyond plain liquid level or displacement tracking; they are crucial in driving innovation and performance throughout numerous industrial operations.

The fostering of magnetostrictive sensing units likewise lines up with the growing pattern of Industry 4.0, where smart manufacturing procedures depend on interconnected systems to boost general performance. By integrating magnetostrictive displacement sensors into automated systems, you allow for continuous tracking and real-time data evaluation, which helps in making informed choices based on the real conditions observed in the field.

With the emergence of digital modern technologies and IoT (Internet of Things), the duty of magnetostrictive sensors is being changed also additionally. By connecting these sensors to networked systems, data from magnetostrictive liquid level sensors and position sensors can be analyzed in actual time, giving understandings that were formerly not available. This has the potential to not only boost keeping an eye on accuracy yet likewise to set off preventative maintenance methods, therefore raising and minimizing operational prices performance.

The future assurances even broader applications for magnetostrictive displacement sensors and liquid level determines. As markets relocate toward a lot more data-driven and computerized environments, the demand for trustworthy, high-performance sensing units will just heighten. Subsequently, producers will make every effort to innovate and boost their items continuously, incorporating features such as remote diagnostics, predictive formulas, and compliance Magnetostrictive displacement sensor with emerging industry standards.

To conclude, magnetostrictive displacement sensing units, alongside their liquid level dimension equivalents, stand for a conclusion of technical innovation and design integrity. They are important to various industries, supplying the accuracy and responses required to keep effective M-series displacement sensor procedures. The option of a suitable manufacturer can dramatically influence the efficiency and durability of the sensors, making it important for services to carefully consider their alternatives. As the commercial landscape develops, so also will certainly the applications of these sensors, ensuring website their position at the center of effectiveness and reliability in measurement innovation.

Christina Ricci Then & Now!

Christina Ricci Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Michelle Trachtenberg Then & Now!

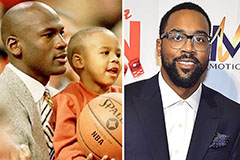

Michelle Trachtenberg Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now!